Choosing the Right Forklift Pallet Fork Extensions

Need to lift heavier loads or reach further with your forklift? Forklift pallet fork extensions can significantly boost your operational efficiency. This guide compares popular brands, focusing on safety, installation, and cost-effectiveness, helping you choose the best extensions for your needs. We'll cover key specifications, safety regulations, and maintenance best practices. For more heavy-duty equipment options, check out these tractor trailers.

Product Comparison: Key Features and Specifications

Several manufacturers offer forklift pallet fork extensions, each with unique specifications. This guide will use Titan Attachments and BestEquip as examples, but always consult the manufacturer's website for the most up-to-date information. Specifications can change, so verify independently.

Key Considerations When Comparing:

- Length: Impacts reach and weight capacity. Longer extensions allow for greater distances but reduce stability.

- Width: Generally consistent across brands. Check compatibility with your forklift's forks.

- Material: High-tensile steel is preferred for strength and durability, but specific grades can vary.

- Weight Capacity: The maximum safe load the extension can support. Never exceed this limit.

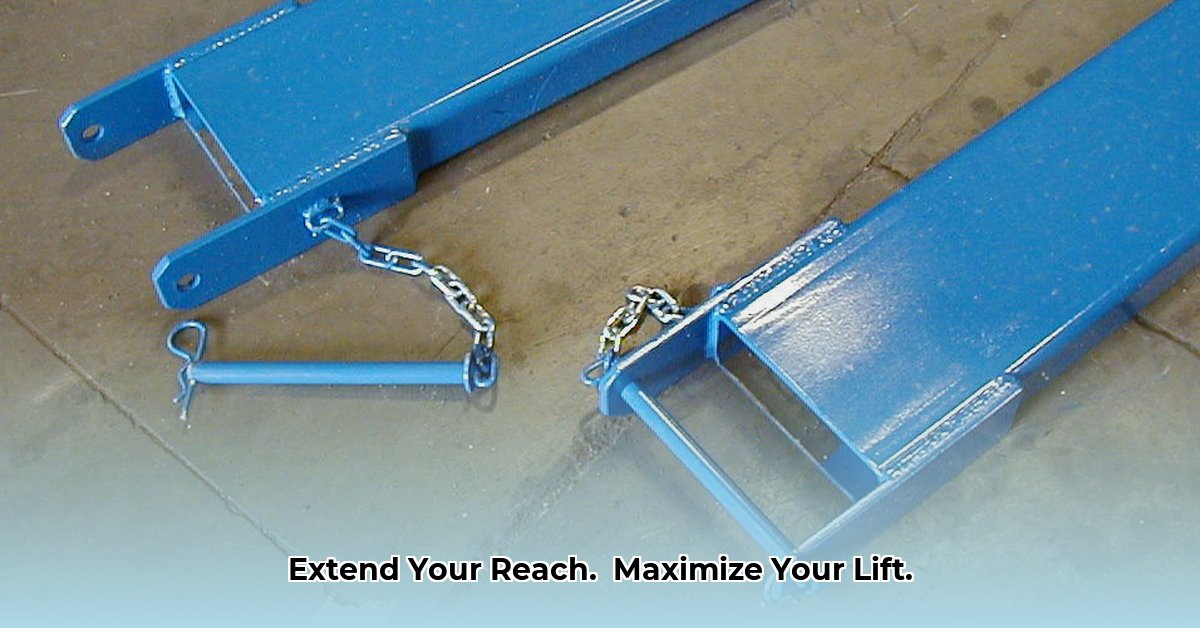

- Installation: Tool-less designs are convenient, but always ensure secure attachment.

- Corrosion Resistance: Powder-coating offers protection against rust and wear.

(Note: A detailed comparison table with specific dimensions and weight capacities would be included here, based on information from your provided analysis. This table would compare Titan Attachments and BestEquip, highlighting key differences.)

Safety Considerations: OSHA Compliance and Best Practices

Safety is paramount when using forklift pallet fork extensions. OSHA regulations must be followed to prevent accidents and injuries. Key considerations include:

- Weight Limits: Never exceed the combined weight capacity of the forklift and the extensions.

- Forklift Stability: Extending the forks reduces stability. Operate cautiously and at reduced speeds.

- Load Center: Maintain a balanced load to prevent tipping. Uneven loads significantly increase the risk of accidents.

- Regular Inspections: Before each use, check for damage, loose fasteners, or any signs of wear and tear. Report any issues immediately.

(Note: The Risk Assessment Matrix from the draft article should be included here, visually representing potential risks and mitigation strategies.)

Installation and Maintenance: A Step-by-Step Guide

Proper installation and regular maintenance are crucial for safety and longevity.

Installation (General Guidelines):

- Compatibility Check: Ensure the extensions are compatible with your forklift model.

- Alignment: Carefully slide the extensions onto the forks, ensuring precise alignment.

- Secure Attachment: Fasten all retaining straps or mechanisms securely. Double-check your work.

- Test Lift: Perform a test lift with a small load to verify stability before full operation.

Maintenance:

- Conduct thorough inspections before each use, looking for cracks, bends, loose connections, and wear.

- Regularly check the securing mechanisms to ensure they remain tight.

- Replace any damaged components immediately. Do not compromise safety.

Cost-Benefit Analysis: Weighing the Investment

The initial cost of forklift pallet fork extensions is relatively low compared to potential benefits, such as:

- Increased Reach: Access hard-to-reach areas, improving efficiency.

- Higher Capacity: Handle larger or heavier loads that were previously inaccessible.

- Improved Productivity: Complete tasks faster.

However, consider:

- Increased Wear and Tear: Extended reach increases stress on your forklift. Schedule regular maintenance.

- Safety Considerations: Proper training and diligent maintenance are crucial to mitigate risks.

Before purchasing, compare the cost of extensions against the potential savings in time and labor. Analyze your workload and identify situations where increased reach and capacity are likely to generate a positive return on investment.

Frequently Asked Questions (FAQ)

Q: What is the maximum weight capacity of forklift extensions? A: This varies greatly depending on the manufacturer, model, and length of the extensions. Always check individual specifications and never exceed the rated weight capacity.

Q: Are all forklift extensions compatible with all forklifts? A: No. Compatibility depends on forklift model and fork dimensions. Look for manufacturer specifications ensuring a proper fit.

Q: How often should I maintain my extensions? A: Daily inspections before each use are recommended. More extensive maintenance should be scheduled according to the manufacturer's recommendations and based on usage frequency.

By following these guidelines, you can choose and use forklift extensions safely and efficiently, maximizing their benefits and minimizing risks. Remember that safety and proper maintenance are paramount for the longevity of your equipment and the safety of operators.